Fully automatic horizontal crossbelt sorter - GEBHARDT SpeedSorter®

New concepts must be developed to meet your requirements, especially with regard to increasing capacity needs and throughput rates. In order to use your storage system as effectively as possible, the connection to the high-performance GEBHARDT SpeedSorter®, which is based on the principle of a crossbelt sorter, is recommended.

The concept

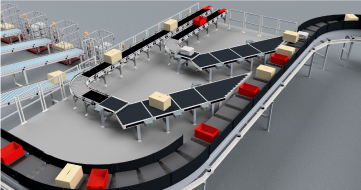

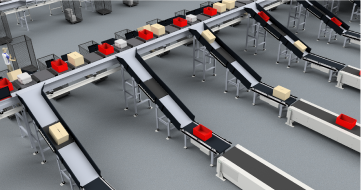

Until now, the various process steps had to be linked by several parallel conveyor lines. The GEBHARDT SpeedSorter®, developed according to the crossbelt sorter principle, enables a continuous material flow concept from one source through the combination with different sorting components such as goods receipt, storage, order picking and dispatch. The implementation in your plant brings enormous economic advantages, as both the internal material flow can be optimized and the available space can be used effectively.

Application examples

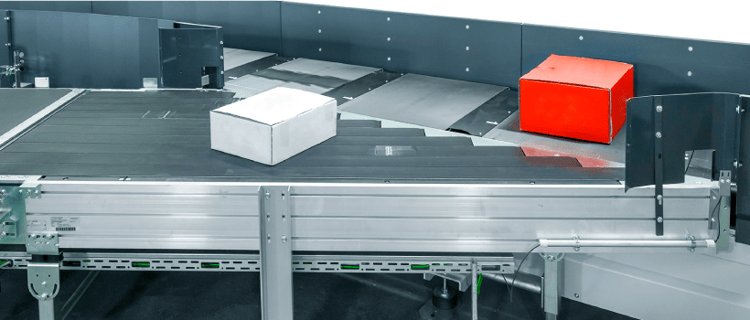

The mechanically driven GEBHARDT SpeedSorter® sorts up to 16,500 conveyed goods per hour at a speed of 2.0 m/s. This sorter allows the sorting of a wide range of products, which reaches from clothing and letters to multimedia products up to packed food. It can transport containers, parcels, polybags (foil-wrapped items) and paperbags of various shapes with dimensions ranging from 100 to 600 millimeters and weights from 100 grams to 35 kilograms. By occupying two carriers (double shells) with one conveyed item, even longer unit loads up to a maximum of 1,200 mm can be sorted.

High-performance sorting systems are particularly interesting for logistics centres in the CEP sector. Due to the booming online trade / e-commerce, the worldwide parcel volume as well as the buying behaviour and the expectations of the customers (e.g. same-day-delivery) have increased strongly in the past years.

Advantages of the GEBHARDT SpeedSorter®

This new product allows the sorting of a wide range of different materials at high speed. From clothing to letters, cartons to food - the GEBHARDT SpeedSorter® covers a wide product range. Totes, parcels, poly- and paperbags in the most varied forms, but also longer unit loads can be transported.

Increased availability

Due to the proven mechanical components and a precise control based on the latest GEBHARDT technologies, the complete system of the sorter is very robust and requires less maintenance. The reliability of the entire system is ensured by the innovative chain tensioning system, the adaptive and automatic minimum quantity lubrication system as well as condition monitoring.

High flexibility through modular design

The modular design and the flexible modular system make it possible to construct and expand your existing plant as required or to adapt it to changing conditions. We offer you a tailor-made individual solution to make optimum use of your available space.

Increased economic efficiency

Due to the high ease of maintenance, the low operating costs and the intelligent control, the GEBHARDT SpeedSorter® is particularly attractive when considering economic aspects.

Precise control and high quality

Thanks to the continuous monitoring of the entire system, the dynamic adjustment of the infeed times and speeds as well as intelligent sequencing, the GEBHARDT control system of the sorting plant leads to a significant increase in efficiency of your distribution and sorting processes.

System competence

GEBHARDT stands for many years of experience in the development of efficient intralogistics solutions and for proven technologies. We therefore recommend the connection to GEBHARDT systems such as GEBHARDT StoreWare® and to the GEBHARDT Galileo IoT® platform

SpeedSorter® = SmartSorter

The system status of your GEBHARDT SpeedSorter® is continuously monitored. The data from the condition monitoring is used for preventive maintenance by predicting the failure time of individual sorter components through the application of intelligent algorithms and the analysis of various operating parameters.